Philips SlimStyle LED

https://trellis.net/article/why-philips-ecodesign-play-paying-more-one-way/

https://www.researchgate.net/figure/Philips-newest-40-60W-incandescent-replacement-the-SlimStyle-LED-lamp-has-low-material_fig3_270207909

https://www.philips.com/a-w/about/environmental-social-governance/environmental/circular-economy.html

Key design solutions include:

Key design solutions include:

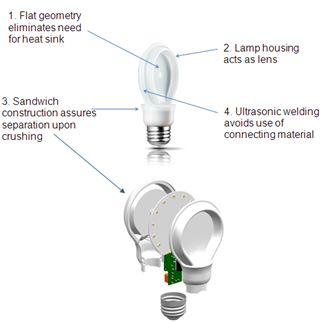

- The housing structure is flat and in close contact with the LED-PCB. The LED-PCB is dimensioned such that the copper present on the PCB takes care of heat spreading, which eliminates the use of a separate aluminium heat spreader.

- The polycarbonate housing is shaped in a way that it also takes the function of the optical lens to distribute the light.

- The LED PCB is enclosed by the housing. The driver PCB is connected to the LED-PCB and the fixture, while the fitting is clamped to the polycarbonate housing. Permanent connections between the various parts are thus avoided.

- The polycarbonate parts are connected by ultrasonic welding such that the connection is strong enough in normal use, but breaks apart when shredded. The other parts of the lamp are then also liberated.1