Only chemically recycled plastics (breaking them back to monomers and re-polymerizing) are truly circular.

- Example: Depolymerizing PET back to TPA and EG monomers → making virgin-quality PET again.

- Similarly, pyrolysis and solvolysis methods are being developed for PE, PP, etc.

- But these are energy-intensive and not yet scaled cheaply.

Common polymers such as polypropylene (PP), polyethylene (PE), ABS Plastic, PC and PS are already recyling at scale.

Design for Recycling guidelines for plastics

- Use common plastics (e.g. ABS, PE, PP, PA, PC, PET, PBT, PC/ABS and HIPS).

- If an alternative plastic is necessary (e.g. engineering polymer or thermoplastic elastomer), use one with a density outside the 0.85 – 1.38 g/cm3 density range of common plastics (e.g. by using particle filled plastics).

- Avoid polymer blends.

- Polymer blends (besides PC/ABS) pollute recycled material streams.

- Avoid glass fiber filled polymers and other composites.

- Minimize the use of additives.

- Thermoset plastics (including rubbers and composites) cannot be recycled. If a thermoset is required, use one with a density outside the 0.85 – 1.25 g/cm3 density range of common plastics.

- Avoid coatings and paints on plastic parts

- They will pollute material streams and possibly change the density of the material.

- Avoid the use of foam

- Do not use plating, galvanizing or vacuum metallization to coat plastic parts.

- This creates a connection between the plastic and metal.1

Highlights

https://www.linkedin.com/feed/update/urn:li:activity:7388862130663485440/

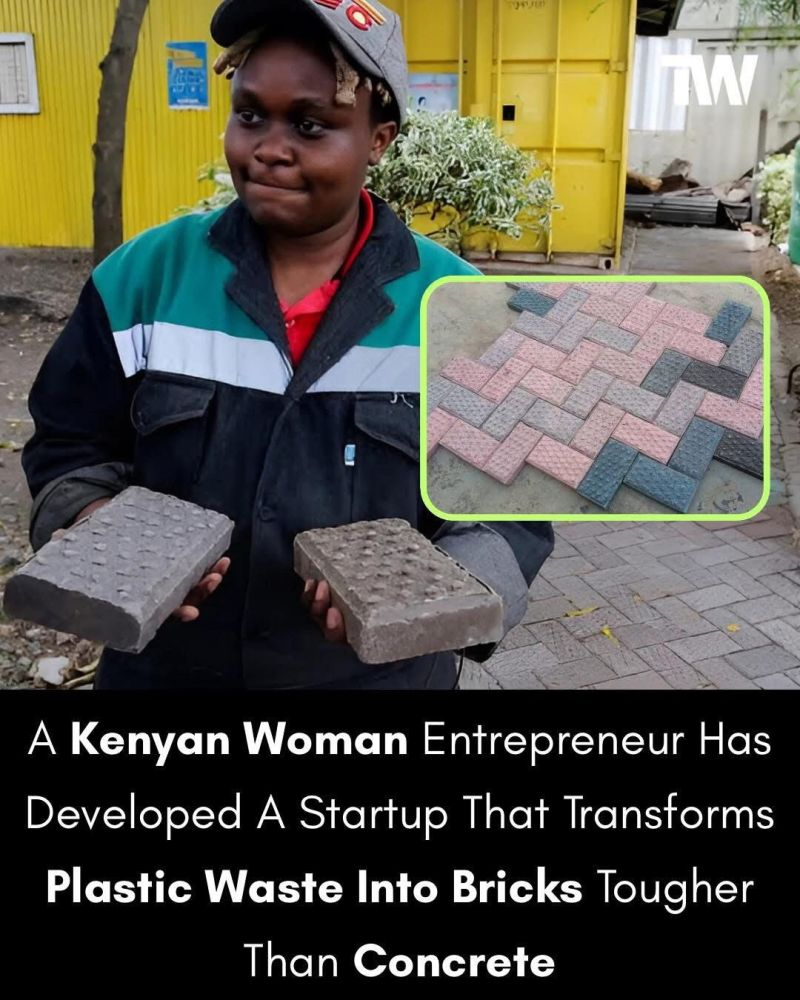

🚧 The impact is extraordinary:

🔹 Plastic waste is melted and compressed into vibrant, lightweight bricks.

🔹 Each brick is 25% stronger than concrete — yet cheaper to produce.

🔹 Thousands of kilograms of plastic are diverted from landfills every week.

🔹 Local jobs are created while reducing carbon and construction costs.